Although machines like CNC waterjet cutters work immediately on food things for cutting, Many others are used for packing or creating cooking equipment. Some typical applications are:

Besides these milling operations we will use the milling machine for the subsequent operations likewise.

The evolution of CNC technology has stored tempo Along with the miniaturization of semiconductor components, enabling producers to fulfill the needs of modern electronics.

Decreased Human Mistake: CNC machines’ automation minimizes human mistake drastically, with precision programming assisting minimize problems for higher dependability in high-stakes manufacturing environments.

These parts in many cases are used in pipelines or refineries. They could be needed in more compact portions to suit specific quantities. The oil and gas industry usually involves corrosion-resistant machinable metals like Aluminum 5052.

CNC mill turning centers, also known as CNC mill-transform machines, Mix precision milling and turning procedures. Milling and turning have constantly been performed on different CNC machines. Nonetheless, combining them into just one CNC machine can considerably simplify the manufacturing system.

A business that designs custom parts for your automotive industry could possibly use a hybrid manufacturing method to build complex geometries and intricate parts. The method begins with 3D printing, wherever a polymer materials is used as a foundation layer. Then, CNC machining refines and shapes the ultimate portion. This mix of processes permits greater layout versatility than either process could achieve By itself.

Electrical discharge machining only works on metals considering the fact that they conduct electricity. It makes use of two electrodes – the tool electrode along with the workpiece electrode. This machining process provides The 2 electrodes shut to one another, but they don't make physical Get hold of.

Bead Blasting: A floor treatment method procedure to get a particular degree of cleanliness and unique roughness over the surface from the workpiece. The surface soon after sandblasting is uninteresting and matt.

To start with, high quality precision machining demands a higher-conclusion cutting tool capable of taking away the material meticulously to match the specified solution Proportions.

Content charges might be diminished by taking into consideration the dimensions in the blank necessary, and the price and machinability of the majority substance (softer alloys are more rapidly to machine).

Just after People records ended up sent to him, Yu explained that given that export controls ended up imposed, “our corporation has no longer transacted with this particular vendor.”

The foods and beverage industries aren’t the primary assumed that involves head when here pondering CNC machining. Nonetheless, these industries count heavily on CNC in numerous areas.

Medical Equipment: Precision is of your utmost value On the subject of healthcare equipment. CNC machining may be used to supply surgical instruments, implants, and orthopaedic devices, for example.

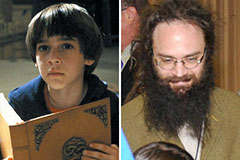

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Kane Then & Now!

Kane Then & Now! Traci Lords Then & Now!

Traci Lords Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!